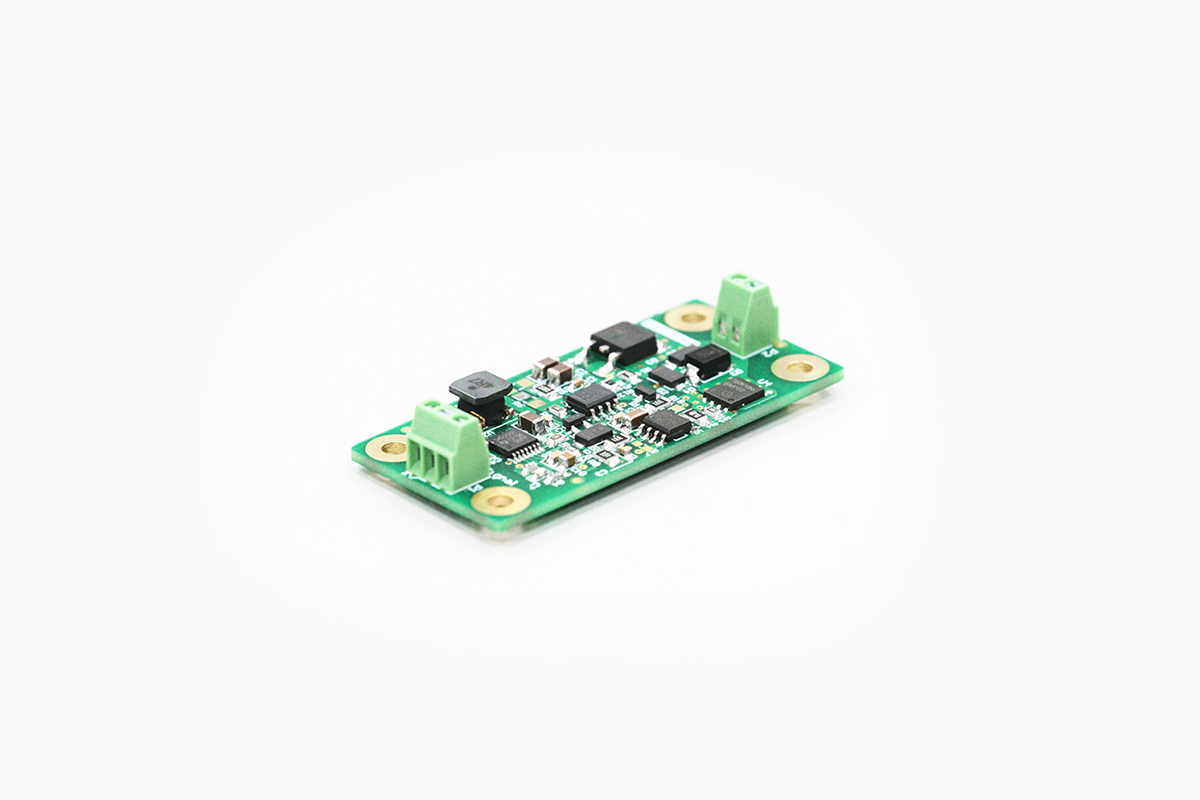

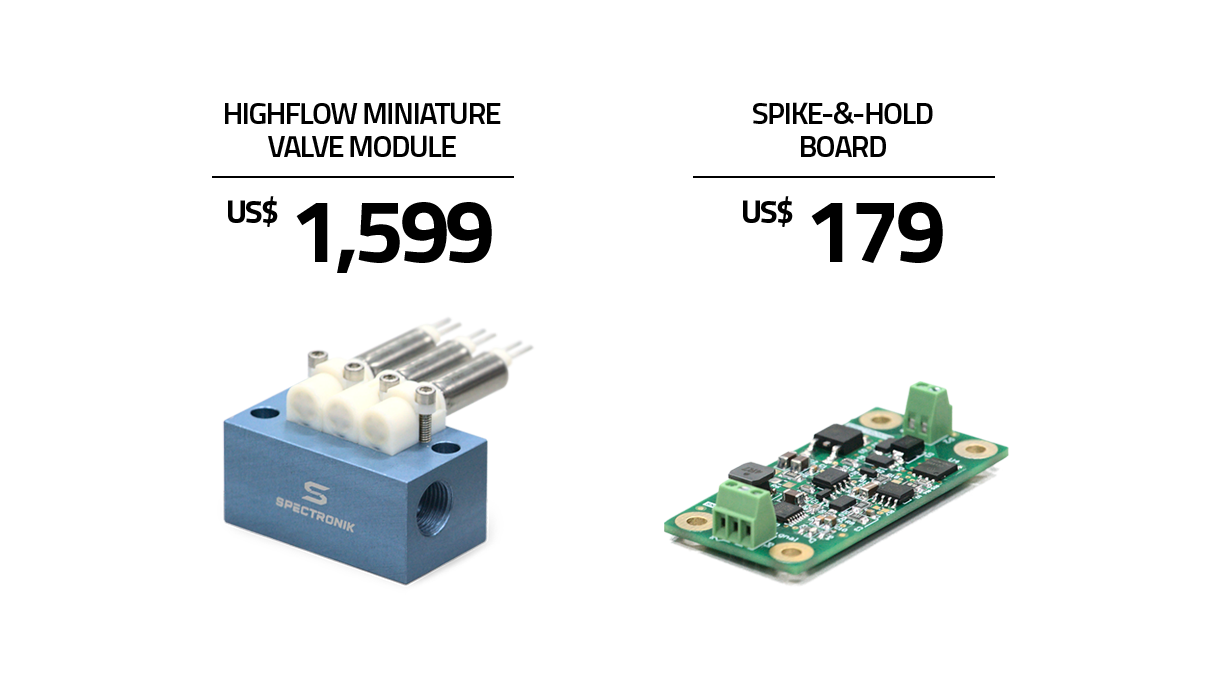

The Highflow Miniature Valve Module and Spike-&-Hold Board are now both available for purchase at our online shop!

To find out more, visit our product pages:

Highflow Miniature Valve Module Spike-&-Hold Board

or contact us at hello@spectronik.com