Singapore’s First Hydrogen Fuel Cell Vehicle Trial On Public Road

Spectronik has successfully obtained all necessary approvals from landowners JTC Corporation (JTC) and government regulatory bodies such as the Land Transport Authority (LTA) and Singapore Civil Defence Force (SCDF) for its Cruiser Hydrogen fuel cell vehicle - paving the way to commence road trial.

Cruiser is a zero emission, fully-electric light commercial goods vehicle capable of carrying up to 1 tonne of cargo. It is powered by Spectronik fuel cell which is designed and manufactured exclusively in-house in Singapore. Cruiser has a driving range of 500km and refilling its on-board Hydrogen cylinders takes just five minutes, presenting an environmentally friendly and operationally efficient transport and logistics solution.

Crusier road trial is expected to begin on 23 October 2023 on pre-approved routes within JTC’s Jurong Innovation District (JID) in western Singapore. The trial will run for an initial duration of one year.

Cruiser Road Trial Aims To Achieve Three Objectives:

Technical

Goals

Business

Goals

Intangible

Benefits

GALLERY

WATCH THE VIDEO

_1701328676.png)

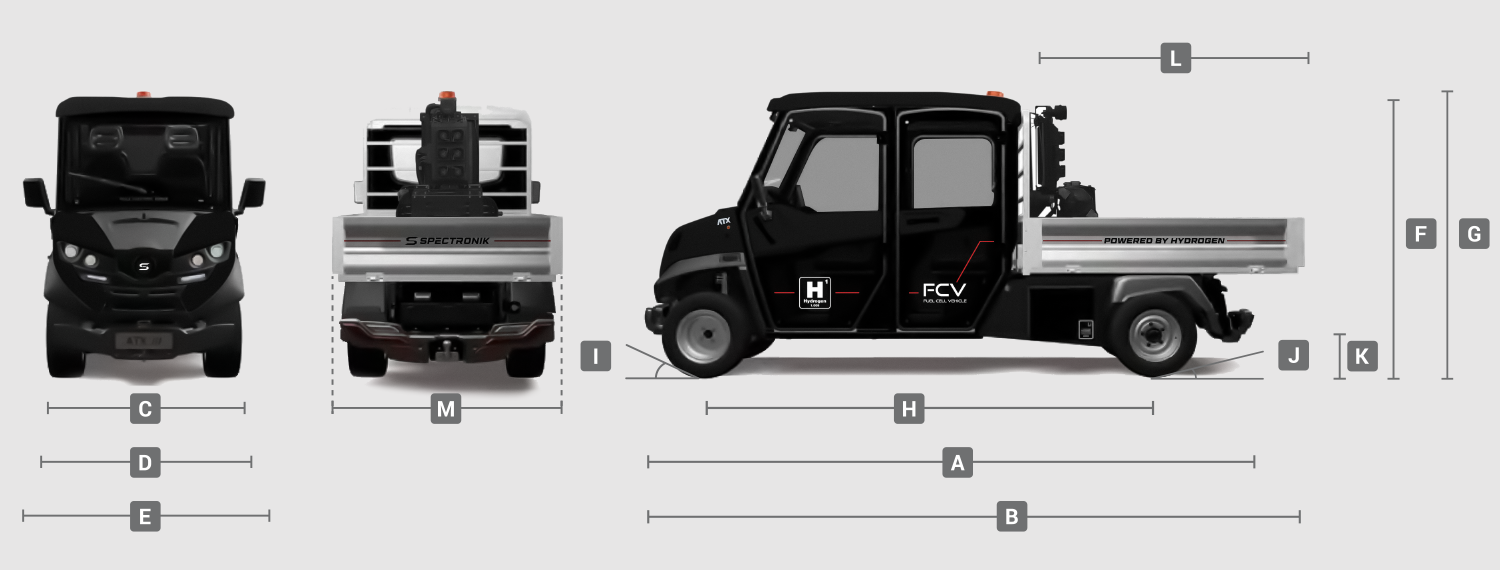

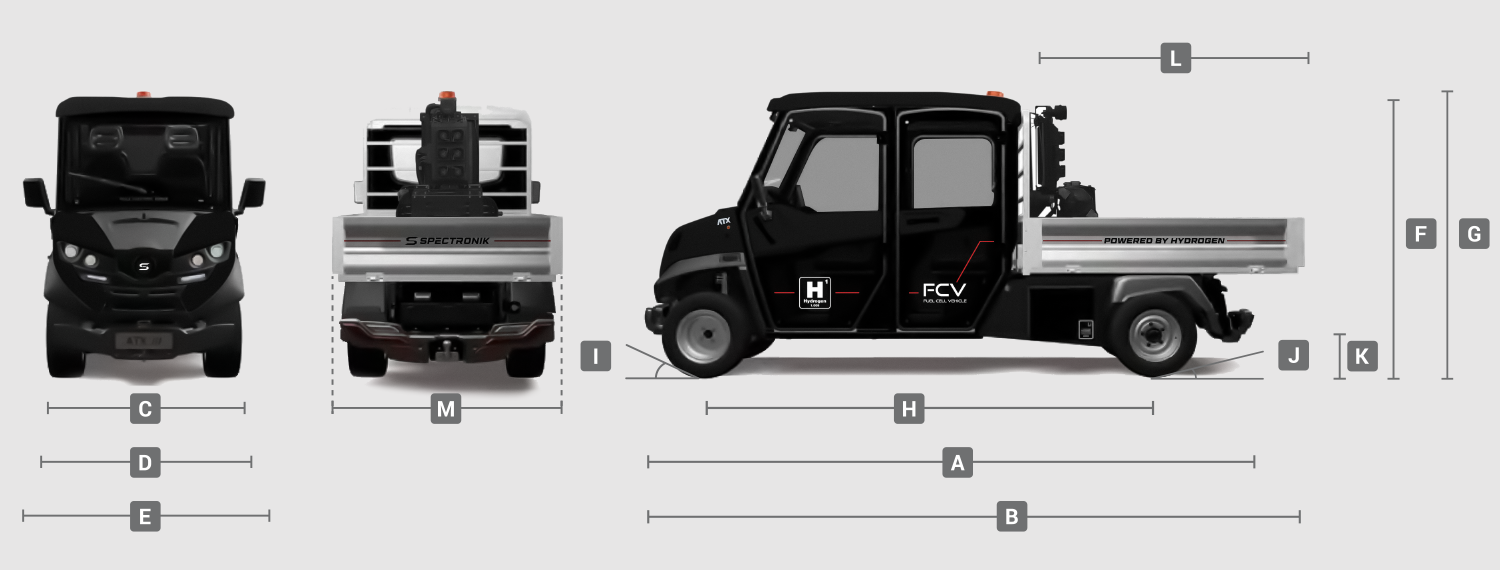

SPECIFICATIONS

WATCH THE VIDEO

_1701328676.png)

SPECIFICATIONS